Refrigerating and Air Conditioning Pressure and Temperature Controls – Household

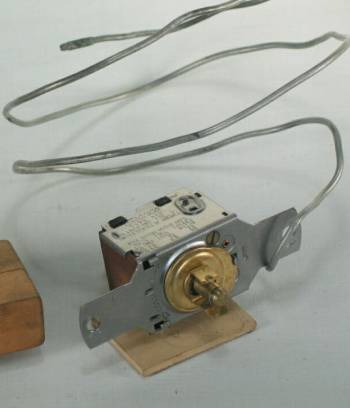

An hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing; driven by a 36″x 3/32″ capillary line with integral power element, the contol was representative a new generation of miniature, snap action controls for original refrigeration and air conditioning equipment manufacturers, as well as for general replacement use, starting in the 1940’s, Ranco, circa 1945.

With this generation of thermo-mechanical, refrigeration thermostat technology the trend was set to move to the end of the century and the introduction of new 21st century control technology in which extended capillary sensing would be replaced by electronic sensing. \r\nIt was to be the last in the series of hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing – the preferred sensing technology of the early 20th century. [See items ID # 142- 151].

The control’s cut-out temperature can be re-calibrated in the field by means of a small internal adjustment screw.

Technical Significance:

The series [see items ID # 142- 151] profiles the evolution of extended capillary tube technology through a myriad engineering design developments and applications. It was a period driven by, and responding to, a new often shameless, marketing hyperbola. For the industry would take full advantage of knowledge from the newly found thermal and fluid flow sciences of the times, as well as of the new materials technology and manufacturing methods of the immediate pre-W.W.II years.

The industry was clearly out to create ever-increasing consumer interest and expectations for a user friendly, fully automated, self-regulating, affordable, mechanically driven cabinet refrigerators for the Canadian home. It was “an automatic refrigerator in every kitchen” following the marketing pattern set by the automobile industry for “an automobile in every garage”, that was the call of the captains of the household refrigeration industry. The perfection of a reliable, affordable, and user friendly, automatic temperature control was critical to the success of this business venture.

This control, representative of the end of the generation of extended, mechanically operated, capillary tube temperature sensors, is a masterpiece of precise engineering and manufacture of the period. Ranco Inc. produced this new generation, of miniature, snap action, capillary line controls for original refrigeration and air conditioning equipment manufacturers, as well as for general replacement use, starting in the 1940’s. Wholesaler’s and jobber’s catalogues of the period list many variations, made to the mounting and performance requirements of the industry.

With this generation of thermo-mechanical, refrigeration thermostat technology the trend was set to move to the end of the 20th century and the introduction of new 21st century control technology in which extended capillary sensing would be replaced with electronic sensing devices.

The contrast between this thermostat in bulk, weight and performance, with the technology of two decades earlier [See items ID 142-151], stands as a remarkable industry achievement. The evolution of the technology would, among other things, support the development of new more elaborate cooling systems, for cabinet refrigerators, with new features and functionality, including automatic defrost and dual temperature cabinets, as well as air conditioners and water coolers.