Pressure Atomizing Oil Burner Equipment and Systems – Fuel Flow and Combustion Controls

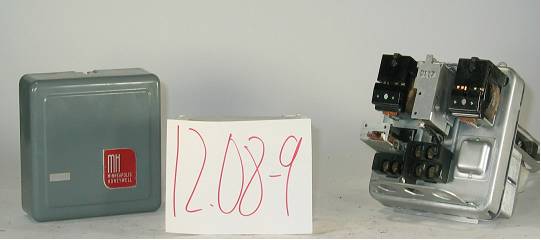

An example of innovative, mid 20th century combustion safety control technology that would dominate the field of household automatic oil heating through much of the balance of the century; stack mounted, bimetal heat actuated safety switching, electro-magnetic relay controlled; equipped for intermittent ignition, heat anticipation, 3 wire room thermostat, Type RA117A, 25 cycle, Minneapolis Honeywell, Toronto Circa 1945. [See also ID#235]

Features:

– Pristine enclosure in high gloss grey, a break in tradition with the “black look” of heating control devices

– Handsome corporate monograph in distinctive Minneapolis Honeywell red

– Original wiring diagram on inside of cover

Technical Significance:

– Of special significance is the 25cycle engineering of this controller, built for the Ontario market in the period prior to frequency standardization, which took place in the closing years of the 1940’s in much of the province. These devices being electro-magnetic were frequency sensitive. The large rear mounted transformer used to provide control circuit power tells the story. The 6o cycle equivalent is shown on item ID#235.

– With the introduction of new generation of integrated, relatively reliable control systems for household heating in the early 1940’s a new era of mass produced technology had arrived, setting the stage for a new, Canadian mass market.

– It combined up-dated, bimetal combustion control technology with the three wire, heat anticipating thermostat, – providing comfort, safety and reliability levels unheard of a decade earlier.

– By the early 1940’s Minneapolis Honeywell’s unitary designed, combustion controller, the RA117A Protectorelay, had arguably become a kind of standard of achievement for the home, automatic, oil heating industry in much of Canada.

– The fragile and potentially poisonous mercury bulb switching of earlier combustion controls was replaced here with quiet, reliable, electro-magnetic and bimetal driven snap action contacts,

– A significant design consideration in the development of unitary, stack-mounted controls was the high ambient temperatures to which they were subjected. High temperature wiring and heat shielding were new design requirements to be dealt with.

– These embryonic, electric automated systems were representative of the earliest introduction of complex systems into the Canadian home. See Note #2

Industrial Significance:

– This pristine control, un-used, was a factory reconditioned, control by Minneaplolis Honeywell, Toronto. It exemplifying the great care taken in recycling of equipment, part of the practice and conservation ethic of the day, delivering

reliable reconditioned equipment to a market that desperately needed it .

– It was a period quite different from that which would exist towards the end of the century, where damaged and un-reliable equipment would be declared expendable, too costly or superseded, as a result of rapid technological, design or manufacturing changes.

– By the mid 1940’s the HVACR industry recognized that a new era in the popularization of automatic home heating equipment was under way. Unitary designed, oil home heating equipment had evolved into a “home appliance”, on which many householders would now become heavily dependent.

– This new, widespread dependency on automatic heating, throughout Canada’s long cold winters, would require the industry to strive for enhanced performance in matters of reliable, maintainable and readily serviceable equipment, with readily obtainable replacement parts.

– Public expectations for 24 hour emergency service was part of the new world of popular technology that had been created. Honeywell and other manufacturers would respond by providing a line of rebuilt controls for field service people to stock for emergency purposes.