Electric Motors – Single Phase Capacitor Start and Capacitor Run Motors

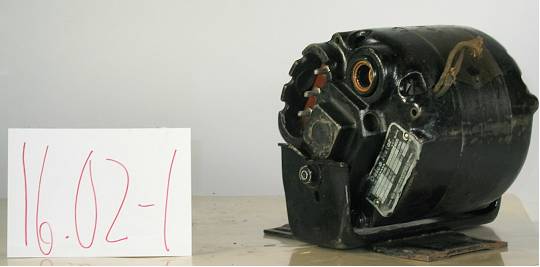

A mid 20th century, high tech, 25cycle capacitor-start motor, an early design engineered for a new generation of high starting torque refrigeration motors made possible by the electrolytic, chemical capacitor, equipped with fuse-style, overload protection, and designed for “V” belt drive applications, with pivoted motor mounting and automatic belt tension device, Delco, Circa 1945.

Features:

Built for 25 cycle, 110 volt alternating current, representative of motor design used in Ontario prior to frequency standardization in the late 1940’s

With a toe crushing weight this 1/6th HP motor weighs in at 35 lbs., illustrating the greater weight of 25 cycle rotating equipment, over 60 cycle a factor in moving to a higher cycle, in order to help reduce equipment costs.

Technical Significance:

Built for 25 cycle, 110 volt alternating current, a rare example, representative of motor design used in Ontario prior to frequency standardization in the late 1940’s

1940’s style, high tech, capacitor-start motor, designed for top mounted electrolytic capacitor [not included]

Representative of a class of innovations introduced by Frigidaire, to provide automatic control of belt tension, using a simple, extension coil spring, with motor pivotally mounted on base plate. Maintaining proper belt tension, on refrigeration compressor drives was a perennial problem, due to close coupling of motor and compressor and large compressor fly wheel diameter.

Includes an early form of overload protector, the fusetron. Socket provided fusetron not included. Over load protection was an on-going challenge through the early years in the development of unitary, fully automated refrigeration equipment, designed to operate un-attended in the home – without the attention of skilled work force.

This type of overload operated much like a standard instant blow fuse, but calibrated to carry the high starting current characteristic of induction loads. Its disadvantage was that it was a non-recycling device, which means that the refrigeration system could be off without the homeowner knowing it. Later devices would be automatically recycling [see ID# 281].

Industrial Significance:

The production of FHP electric motors under the Delco name was a marker of the post W.W.II doom in Canada’s appliance industry. Delco was a brand name, held by General Motors, under which auto electric components were manufactured and marketed. McKinnon Industries was a feeder plant to GM, located in St Catherines

The development and commercial production of the capacitor-start single phase FHP motor, starting in the mid 1940’s was a seminal event in the history of the HVACR field. The capacitor-start motor would come to replace the more costly and complex repulsion induction motor, RI [See Group 16.01], with one with fewer moving mechanical parts, quieter, more reliable and maintainable, typically at lower cost. By allowing for electrical switching between starting and running windings, it would facilitate external relay control, rather than internal mechanical mechanisms, as with the RI motor. It would therefore be amenable for use in hermetically sealed refrigeration systems.

Early experimentation, leading to the eventual commercial development of the FHP, capacitor start-motor, began with the work of Steinnmetz [American engineer and inventor 1865 – 1923], 40 years before. But commercial production had to await the development of practical capacitors of sufficient capacity, the chemical, electrolytic capacitor. Early, paper and foil style capacitors, large enough to provide the required phase shift for motor starting, where larger than the motor itself, and were subject to short operating life span [see Reference 3]

Conventional industrial practice for refrigeration systems, with compressors operating at conventional speeds, in the 1930’s through 60’s, saw these motors attached by “V” belt drive to the refrigeration compressor with a compressor fly wheel about three times that of the diameter of the motor pulley. [see reference #4]. Maintaining belt alignment and tension was a constant challenge, due to close coupling of motor and compressor for space saving.