Electric Motors – Single Phase Capacitor Start and Capacitor Run Motors

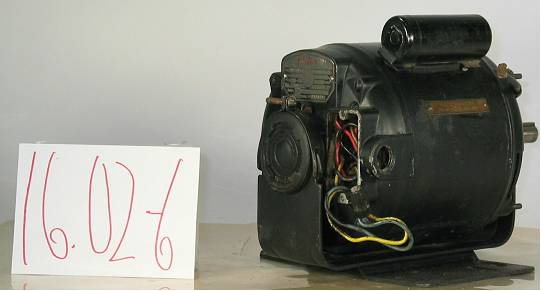

A mid 20th century, high tech, 60 cycle capacitor-start motor, made possible by the electrolytic, chemical capacitor and inherent, heat overload protection, with automatic reset, vibration isolating, rubber, torsion motor mount, engineered by a small, start-up Canadian Company, it tells many stories of the exceptionalities of its life and times. Tamper, Circa 1955.

Features:

Carries Ontario Hydro brass identification plate: HEPC Stock NO. P56-02-22-12-308-0002

Technical Significance:

An historical artifact of the post W.W.II years in the evolution of FHP motor technology in Canada, which although un-remarkable in matters of innovation and excellence, tells important stories of the exceptionalities of its times:

Of one of the largest and most sophisticated engineering mega-projects in Canadian history, frequency standardization in Ontario

The remarkable, although short lived period of expansion of the Canadian FHP motor manufacturing industry,

The manner in which the industry attracted new entrance, as small start-up companies, such as Tamper, as well as large manufactures with almost un-limited economic and engineering resources to draw on, such as GE [see ID#285 and 284]

Representative of FHP, capacitor start, induction motor technology, built for the post W.W.II rapidly expanding refrigeration equipment market, equipped with engineering features new for the period, including:

Vibration isolating, rubber, torsion motor mounts; Electrolytic, chemical capacitor technology; High tech inherent, overload, thermal protection with automatic reset.

The motor exemplifies the latest in automatic over load protection, an on-going challenge through the early years in the development of unitary, fully automated refrigeration equipment, designed to operate safely, un-attended in the home.

The motor exemplifies increasingly sophisticated developments in the field of electrolytic condensers, on which the capacitor start motor depended for its performance. Capacitors were getting smaller and more reliable, as well as appearing in more sophisticated, high tensile strength plastic enclosures sealed against moisture and with built-in, easy release, snap mounting brackets

The motor stands as a marker of the golden age in the post W.W.II expansion of the refrigeration industry in Canada, a period which saw the development of the commercial refrigeration market, based on open system refrigeration technology serving food stores, confectioneries, institutions and the like with fractional horsepower belt driven equipment, demonstrating remarkable versatility and inventiveness. It would be the last great period of expansion prior to the rush to re-equip the market with a new generation of hermetic [sealed] motor/compressors. Here the motor and compressor would both disappear from, sight both sealed in a single enclosure. The refrigeration motor, and the technology that made it possible, as it appears here, would disappear forever.

Industrial Significance:

The development and commercial production of the capacitor-start single phase FHP motor, starting in the mid 1940’s was a seminal event in the history of the HVACR field. The capacitor-start motor would come to replace the more costly and complex repulsion induction motor, RI [See Group 16.01], with one with fewer moving mechanical parts, quieter, more reliable and maintainable, typically at lower cost. By allowing for electrical switching between starting and running windings, it would facilitate external relay control, rather than internal mechanical mechanisms, as with the RI motor. It would therefore be amenable for use in hermetically sealed refrigeration systems.

Early experimentation, leading to the eventual commercial development of the FHP, capacitor start-motor, began with the work of Steinnmetz [American engineer and inventor 1865 – 1923], 40 years before. But commercial production had to await the development of practical capacitors of sufficient capacity, the chemical, electrolytic capacitor. Early, paper capacitors, large enough to provide the required phase shift for motor starting, where larger than the motor itself, and were subject to short operating life span [see Reference 3]

Conventional industrial practice for refrigeration systems, with compressors operating at conventional speeds, in the 1930’s through 60’s, saw these motors attached by “V” belt drive to the refrigeration compressor with a compressor fly wheel about three times that of the diameter of the motor pulley. [see reference #4]. Maintaining belt alignment and tension was a constant challenge, due to close coupling of motor and compressor for space saving.