Refrigerant Flow Controls – Household

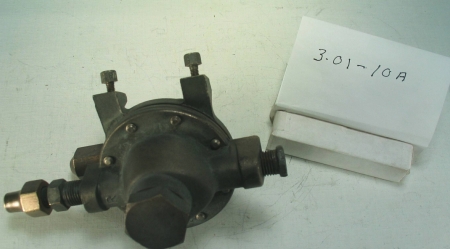

An early automatic, adjustable expansion valve, a pioneering contribution by Frigidaire to the embryonic years of the refrigeration industry; housed in a 4 lb. solid cast brass body with integral two point mounting bracket, with galvanised over coat; pressure actuated 2 inch diaphragm; engineered for sulphur dioxide, the then newly developed, low pressure refrigerant of choice; Model N, Frigidaire, circa 1929. [On of a set of two, see #ID 180]

Technical Significance:

A rare specimen of a self-regulating, spring compensated, automatic expansion valve, one of the earliest in production by Frigidaire, used to maintain cooling units [evaporators], in mechanically cooled refrigerators, at the desired refrigerant pressure.

This artifact of history tells the many stories of early adoption of this particular fluid flow technology. After a brief flurry of excitement over the use of costly and delicate float operated devices, as a more efficient means of flow control, industry engineers would return to the automatic expansion valve in the early 30’s. But by then the automatic expansion valve would be a smaller and much more precisely calibrated and efficient device. While the automatic expansion valve was less efficient in its effective use of evaporator surface than high and low side float systems [See HHCC Series 3.01 artifacts], it had the advantage of reliability and price, as well as serviceability.

The valve taken out of service in the 1950’s attests to its robust nature, with an operating life of 20 years and more.