Refrigerating and Air Conditioning Pressure and Temperature Controls – Household

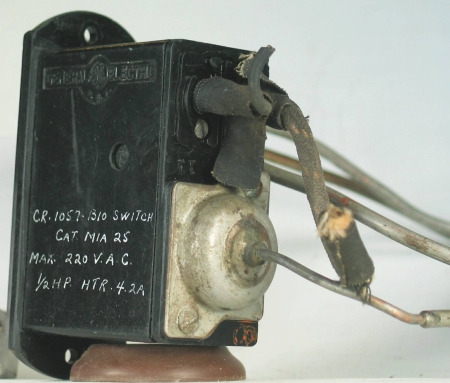

An hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing, with compact internally enclosed bellows and equipped with sophisticated manual reset, electric motor overload protection, featuring motor lock-out viewing window, showing flag on shutdown, enclosed in beautifully moulded, gloss black Bakelite case, with original wiring tag ends, General Electric, circa 1936

One of a series of early, hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing – the preferred sensing technology of the mid 20th century. [See items ID # 142- 151]. The genre would give way by the end of the century to electronic sensing methods.

Technical Significance:

The series [see items ID # 142- 151] profiles the evolution of extended capillary tube technology through a myriad engineering design developments and applications. It was a period driven by, and responding to, a new often shameless, marketing hyperbola. For the industry would take full advantage of knowledge from the newly found thermal and fluid flow sciences of the times, as well as of the new materials technology and manufacturing methods of the immediate pre-W.W.II years.

The industry was clearly out to create ever-increasing consumer interest and expectations for a user friendly, fully automated, self-regulating, affordable, mechanically driven cabinet refrigerators for the Canadian home. It was “an automatic refrigerator in every kitchen” following the marketing pattern set by the automobile industry for “an automobile in every garage”, that was the call of the captains of the household refrigeration industry. The perfection of a reliable, affordable, and user friendly, automatic temperature control was critical to the success of this business venture.

GE, often viewed by their competitors as a “me too manufacturer”, where household technology was concerned, was capable of moving in and out of a field, as the consumer market place seemed to warrant. They would typically follow the industry’s recognised leader in a field, in this case Ranco.

The engineering know how and the capital resources seemingly available to the company made it a formidable competitor, even if in the short run. Few controls by GE seem to survive to the present day, by comparison with Ranco, suggesting that their inroads into this particular market was, in fact, relatively short lived.

The sophistication of the design and engineering demonstrated here is impressive for the 1930’s, demonstrating what a formidable competitor the company could be – in the short term.

The original wiring tag ends demonstrate the appliance trade wiring practices of the mid 1930’s, including the use of twisted, cloth covered lamp cord and “friction” tape