Refrigerating and Air Conditioning Pressure and Temperature Controls – Household

This highly unusual hydraulic bellows actuated, automatic temperature control, employing extended capillary tube sensing, was an aberrant event in the temperature control field of the period, related to an aberration in the field of household cabinet refrigerator manufacturing in Canada. The large somewhat clumsy device, in gloss Bakelite enclosure with etched cover in pea green, identifies the application with the ILG Electric Ventilating Co, with Canadian presence in Renfrew, Ont; equipped with large internally enclosed bellows, long capillary tube, and large auxiliary mounted manual reset motor overload protector, the device appears as a one-off design produced by the control manufacturer to meet ILG’s unique specifications, Cutler-Hammer, circa 1938.

One of a series of early, hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing – the preferred sensing technology of the mid 20th century. [See items ID # 142- 151]. The genre would give way by the end of the century to electronic sensing methods.

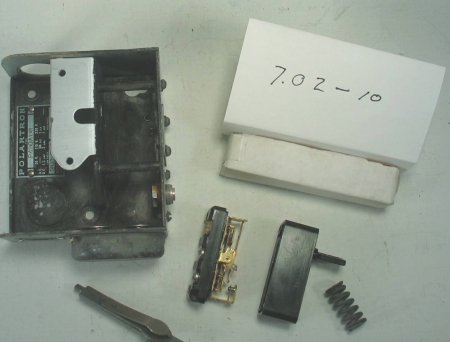

Original wiring harness, tag end, in rubber covered, two conductor stranded copper

Large paper and foil wound condenser to reduce contact arching.

Technical Significance:

The series [see items ID # 142- 151] profiles the evolution of extended capillary tube technology through a myriad engineering design developments and applications. It was a period driven by, and responding to, a new often shameless, marketing hyperbola. For the industry would take full advantage of knowledge from the newly found thermal and fluid flow sciences of the times, as well as of the new materials technology and manufacturing methods of the immediate pre-W.W.II years.

The industry was clearly out to create ever-increasing consumer interest and expectations for a user friendly, fully automated, self-regulating, affordable, mechanically driven cabinet refrigerators for the Canadian home. It was “an automatic refrigerator in every kitchen” following the marketing pattern set by the automobile industry for “an automobile in every garage”, that was the call of the captains of the household refrigeration industry. The perfection of a reliable, affordable, and user friendly, automatic temperature control was critical to the success of this business venture.

The Cutler-Hammer Co. of Milwaukee Ill., who made its name in the electrical switching business in the 1930’s was encouraged to enter the automatic temperature control field in this period of rapidly developing pre W.W.II consumer markets. The engineering capacity of the company and its ability to respond to unusual requests is well illustrated by the atypical design configuration developed here for ILG, with Canadain facilities in Renfrew Ontario.

Among the significant features are:

– The original wiring harness, tag end, in rubber covered, two conductor stranded copper, illustrating the early construction and design of these cables, and their application to the home appliance market of the period

– The large paper and foil wound condenser, hanging from the back of the control, apparently used to reduce contact arching. It was a period in which there was relatively little codified engineering experience on the design of small, alternating current switching devices. It is unclear whether the condenser was part of the original product engineering, or an after-market, field adaptation.

– The control enclosures in gloss black Bakelite, with attractive etched cover plate, with logo and script in pea green is an example of the early attempts at industrial design. The control was clearly intended to be visible and user friendly part of the Canadian household. This had not been a major priority manufactures here-to for.

– The costly, 24 inch, copper capillary line, with large 3/8 inch control bulb reflects much more commercial control design practice of the period, than residential. The relatively large and overall clumsy nature of the control may well reflect ILG’s new arrival in the consumer product field. Its engineering experience having been primarily in commercial and industrial applications [see reference below]