Refrigerating and Air Conditioning Pressure and Temperature Controls – Household

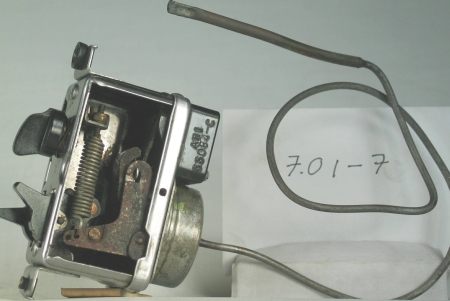

An hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing, equipped with manual reset, electric motor overload protection, and a semi-automatic defrost feature, enclosed in new compact stainless steel case, Ranco, Type KR, circa 1945

One of a series of early, hydraulic bellows actuated, automatic temperature controls, employing extended capillary tube sensing – the preferred sensing technology of the mid 20th century. [See items ID # 142- 151]. The genre would give way by the end of the century to electronic sensing methods.

Technical Significance:

The series [see items ID # 142- 151] profiles the evolution of extended capillary tube technology through a myriad engineering design developments and applications. It was a period driven by, and responding to, a new often shameless, marketing hyperbola. For the industry would take full advantage of knowledge from the newly found thermal and fluid flow sciences of the times, as well as of the new materials technology and manufacturing methods of the immediate pre-W.W.II years.

The industry was clearly out to create ever-increasing consumer interest and expectations for a user friendly, fully automated, self-regulating, affordable, mechanically driven cabinet refrigerators for the Canadian home. It was “an automatic refrigerator in every kitchen” following the marketing pattern set by the automobile industry for “an automobile in every garage”, that was the call of the captains of the household refrigeration industry. The perfection of a reliable, affordable, and user friendly, automatic temperature control was critical to the success of this business venture.

The Type KR series while found on household cabinet refrigerators was most often found on small unitary commercial applications, such as beverage coolers, ice cream cabinets, water coolers, and reach in cabinet refrigerators.

The control with its corroded mechanism illustrates a common cause of failure, in small unitary applications, subject to condensation and water leaks.

Industrial Significance:

see above